How to optimize B2B and DTC order management to fulfill and invoice more orders faster

- Analyze/Organize

- Allocate

- Exceptions

- Automate/Notify

- Invoice

- Get Paid

Joined up Sales, Fulfillment, and Accounting

One system: Order to Cash streamlined

Your SKUs aren't barcoded

You probably aren’t using barcodes if your just starting out, or the number of products in your catalog is small, or if you just prefer to manage your stock by hand and sight. A system with no Warehouse Management System (WMS) will work well for you.

Your SKUs are barcoded

If your products are barcoded, then using the WMS (Warehouse Management System) will accelerate your order fulfillment workflows. There are no additional fees for adding the WMS. 🙂

Process high volumes of orders on AutoPilot.

Orders of magnitude automated

Eliminate effort, go faster, do more.

Our customers process hundreds of orders a day. The AutoPilot feature built into Salesorder enables users to create rules that automate parts or all of the order workflows.

Orchestrate Automations

AutoPilot rules leverage the comprehensive automation in the Sales Order and other key Sales transaction lists.

Organize orders by channel

Multichannel Orders

One view of ALL orders by channel.

Orders from your sales channels flow into one Order List in Salesorder. ‘Origin’ details on orders identify which channel.

Order Quality

Approve Orders

All incoming orders can be automatically set to a status of ‘Pending’.

You can manually or automatically change the status of the order to ‘Approved’ so they can be moved forward for prioritization, allocation, and picking.

You can configure users with permissions to approve orders.

Create and prioritize Order Queues.

Organise orders into Queues, and prioritize Queues by stock availability, required date, customer, value, etc.

Prioritize Orders within Queues

You can drag and drop Orders within Queues to organize their priority for stock allocation and picking.

Prioritize Orders by Earliest Ship Date.

Based upon what you have on Purchase Orders and when their stock will arrive, your system can calculate and highlight what Sales Orders can be shipped when (Earliest Ship Date).

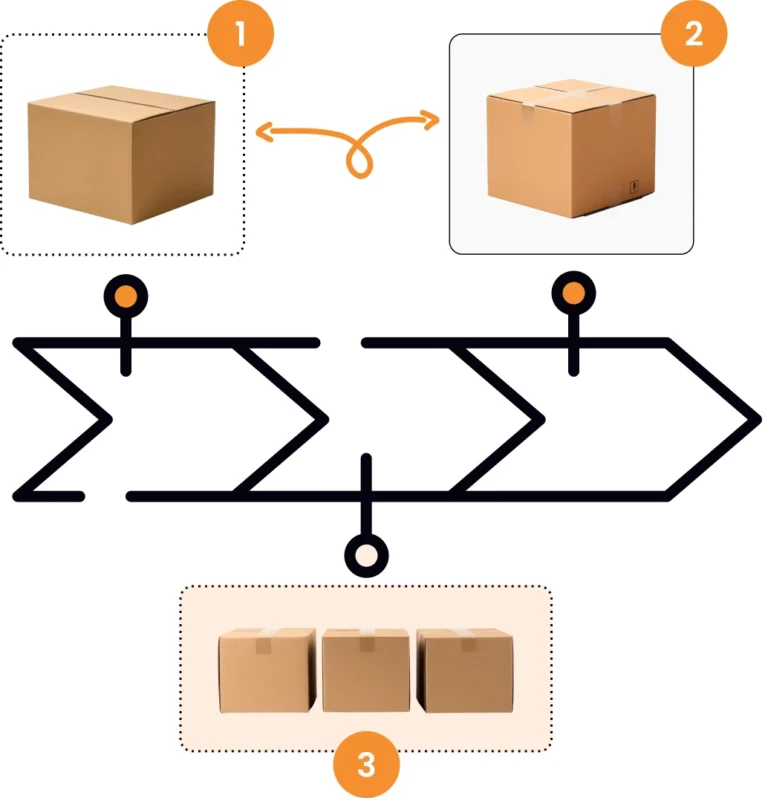

Stock allocation?

A function to check stock availability and ring fence it for each order. Allocation reduces the free stock level.

Intelligent Sales Orders

Prior to stock allocation, Red, Amber, and Green Indicators on Line Items display to what extent Free stock can be allocated, i.e. fully, partial, or none.

Configure allocation automation

Set rules to auto allocate/not allocate stock on new orders.

Bulk stock allocation

Select and simultaneously allocate stock to multiple orders.

Edit stock allocation on Orders

Manually intervene to adjust allocated quantities.

Precisely manage and track order journey and inventory accounting

‘Shipment,’ the Pick, Pack, Ship nerve center

Shipments in Salesorder eliminate the complexity and errors inherent in managing multiple deliveries from one Sales Order.

One Order, multiple Shipments

You can create one or more Shipments from a Sales Order. Each Shipment manages and tracks the Pick, Pack and Ship process.

Shipment journey status

Shipments back propagate data to tell their parent Sales Order how many SKUs are being processed, and where they are in their pick, pack, ship journey, for example, ‘In picking’, ‘All picked’, ‘In packing’, etc.

Shipment visibility for all stakeholders

Shipments give users and Customers complete visibility of where SKUs are in their journey. Customers and sales reps can view Shipment status from the TAP (B2B ecommerce portal). Salesorder users can see the Shipment status on the Shipment Lists in Salesorder and the Warehouse Management System.

Shipping instructions and outcomes

As well as tracking quantities of SKUs that have been picked and packed, Shipments instruct and record the shipping process.

Dimensions, weights, volumes, shipping vendor and method, tracking number, # of packages/pallets are all stored on the Shipment.

Pick Lists and Packing Lists are all generated from the Shipment. These Documents can be customized to display information, i.e. product images.

Merge Shipments

Salesorder’s built in WMS (Warehouse Management System) enables users to merge multiple Shipments being dispatched to a single Shipping Address.

Stock, Balance Sheet and Stakeholder Harmony

Shipments model real world stock movements for stock and balance sheet accuracy

The accounting in most back office systems insist the Sales Invoice changes the on hand stock quantity.

In the real world we’re sure you’ll agree that shipment of an order and creation of the Invoice are two separate events.

To ensure accuracy of on hand and free stock at all times, the Shipment changes the on hand stock level and updates the balance sheet correctly.

Customers on precisely the same page

Shipments track and record the data Customers most want to know about when they’ve placed their Order. “Where is it?” is the most common question. You have two options:

Automated Email

Automatically email updates as and when the Shipment data and status changes. We include email templates and can automate this.

B2B ecommerce portal - real-time view

Give your Customer access to the TAP (Trade Acceleration Portal) and direct them to login and check. The TAP has a list of Shipments that expose all of their data and progress in real time.

Shipping solutions

Get Shipped Done

Your Shipping vendor transactions for Customer Shipments are either ‘Small Parcel’ or ‘Freight’ (FTL, LTL).

Small Parcel

Depending upon which carriers your working with, i.e. UPS, FedEx etc, and how the complexity of your shipping we’ve both the understanding and solution. We have direct integration with UPS and Fedex, and integrations with Shipstation and Easypost.

Freight

If you’re working with Freight brokers, Freight forwarders or individual LTL/FTL we can help streamline your shipping process.

Automate Invoicing of Shipped Orders

Bulk create and email Invoices

From the Order List, and with a couple of clicks you find and select orders that are ready to ship and bulk create their Invoices.

Then, from the Invoice List, you can email the Invoices to your Customer with a couple of clicks.

Because Salesorder has email templates and is connected to your email platform, sending Invoices in bulk is quick and easy.

Because Salesorder’s accounting and order management work in harmony, Orders, invoices, and the underlying accounting work together in one system. This means your accounting and inventory are always in sync.

Warehouse management system is included and optional at no extra cost

Manage Locations, SKUs and their movements, and Shipping at scale.

Enterprise grade Warehouse Management System

If your SKUs are barcoded, and your stock room is scaling you can turn on the built in Warehouse Management System (WMS).

Barcode Scanners

You can harness the efficiency of barcode scanning to accurately track stock and its movements. Warehouse managers can oversee and control every aspect of barcode operations from the WMS Console.

Incoming Purchase Orders

Efficiently and precisely receive POs and put away stock to pre-designated or protected Locations.

Shipments to Customers

All Shipments created appear in the WMS. WMS pickers see these in their Barcode scanners, Warehouse managers see them in their Console. Shipped gets done.

What does the WMS do?

The WMS can manage multiple warehouses and the physical elements of the SKU journeys. You can:

Configure Locations

Locations in the WMS can be configured to behave according to rules you set for how they will behave. For example, you can model Containers on the Water, Consignments, Quarantine, SKU specific locations etc.

Track SKU instances

Track each instance of every SKU (useful if you need Lot tracking, Sell by dates, Batch #s, or Serial numbers).

SKU Movements

Where each SKU is and how and why it got there.

FAQ

We process very large volumes of orders, can you manage this?

Many customers process more than 5 K orders per month (avg.166/day). We host at Amazon AWS, which enables us to swiftly turn on additional capacity. As a mission-critical platform, we continuously monitor performance KPIs and thresholds.

Central to our engineering strategy is the identification and implementation of performance improvements.

Some of our customers have been assigned dedicated servers to mitigate ‘noisy neighbor’ issues.

How much of the order processing can be automated?

AI Robots will soon be in many warehouses. We believe they will begin to replace manual pickers. Our software could automate everything else in the order journey.