How to fulfill every order on time with minimum inventory and minimum use of working capital.

- Reduce excess

- No guesswork

- Painless Forecast

- Auto-create POs

- Forecast Promos

Used by 2500 + customers. Enterprise grade forecasting for wholesalers of all sizes

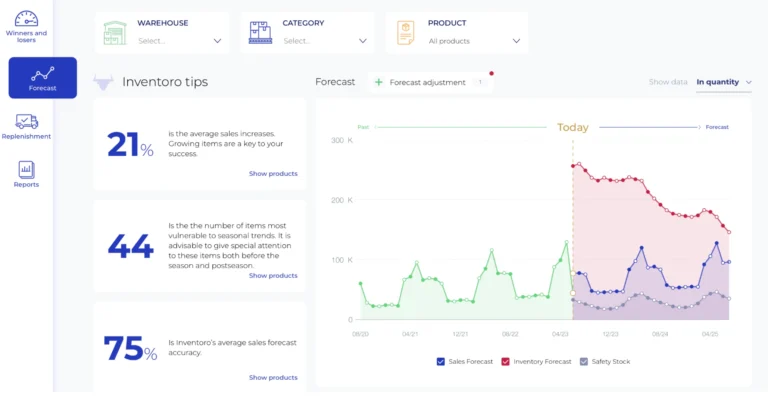

Automated, accurate, forecasts delivered every day

How does inventory forecasting work?

Excel forecasting: painful and a complete waste of time.

We surveyed hundreds of wholesalers who told us, the average time spent on forecasting and purchase orders per month is between 20 and 80 hours. They were unanimous that Excel makes it complicated and painful.

No pain, no wasted time. We’ve automated and simplified the process.

Continuously learns your supply and demand patterns

Our inventory forecasting software for wholesalers constantly tracks every SKU to continually learn its supply and demand history.

Daily accurate forecasts

At the end of every day we use artificial intelligence infused with over 15 years of experience to generate an accurate, up to date sales and corresponding inventory forecast.

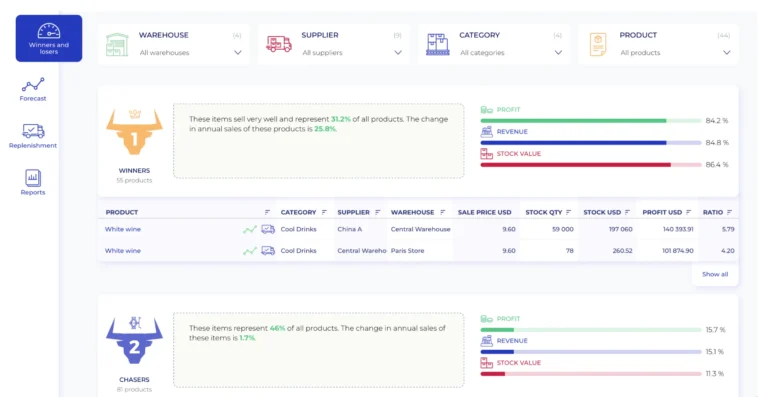

Buy, sell, stop buying, stop selling?

The forecast highlights the winners, chasers, and losers, together with their respective profit, revenue, and value for forecasted sales of the inventory.

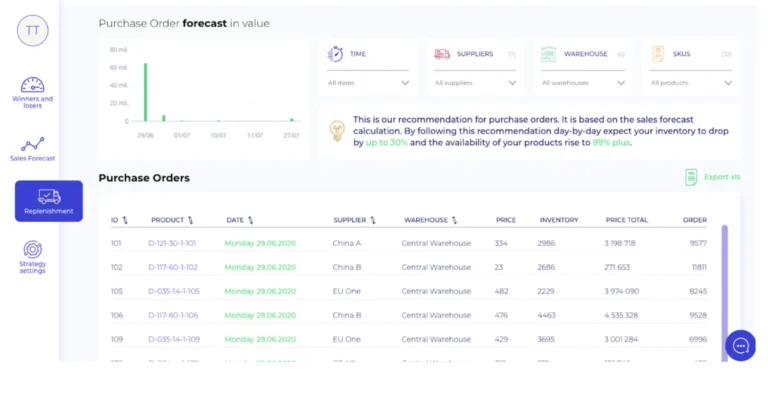

Automatically present purchase proposals

You specify supplier specific parameters such as lead time and purchase order period. Our software presents proposals for replenishment of your inventory.

Automatically create purchase orders

You select and fine tune the proposal, and the system automatically creates the purchase orders for your suppliers.

Intuitive and easy to explore dashboards

Too much stock?

Our inventory forecasting automatically analyzes supply chain and SKU sales to identify where you're overinvesting in excess stock.

Reduce excess stock

Our solution shows you how to significantly reduce your inventory size (often by 40%), while still keeping your inventory items available to customers when they need it.

Free up cash for growth

Eliminating excess gives you the opportunity to reallocate or throttle your working capital spend to support your growth.

Reduce excess inventory by 40% and release cash

Eliminate ‘guesstimates’

16 years of development to perfection

Our inventory forecasting solution is the one with most advanced calculations. It’s so advanced, it can easily compete with the most advanced forecasting software on the planet.

Compute the most accurate forecast of future sales

In most cases, we forecast sales for a product at a particular warehouse or a store at the lowest possible level. Under certain circumstances, we may be able to refine the forecast even more and thus predict unique sales to a customer.

Learn your seasons

Our algorithm can identify extreme seasons, such as Christmas or extremely seasonal items like Easter eggs.

Analysis of stockouts

Identify and subsequently analyze stockout periods with no stock on hand. This data is then used to compute lost sales at stockout of a specific item in your warehouse.

Evaluate losses in revenue and profit that the company experiences due to the stockout and to compute the desired service level.

Straighten historical sales and thus provide an appropriate input to sales forecasting. The sale forecast must reckon with the fact that sales would have continued if there had been no stockout.

The holy grail of inventory management is not only finding the perfect balance between supply and demand, but more importantly maintaining this balance over time.

Beyond humanly possible.

The primary benefit of automation in replenishment lies in its ability to surpass the limitations of the human brain, which cannot possibly remember and evaluate all the myriad possibilities and factors in play.

So many calculations take place in sales forecasting that it’s impossible to evaluate them all on paper or Excel, not to mention in a business owner’s head.

Calculate new order lists every night.

Every night we calculate and report a list of SKUs sorted by the urgency which the system recommends you order them. The further down the list, the longer you can still wait to make an order.

Guaranteed Accuracy

We guarantee with the greatest accuracy that by following our lists you will be in perfect position to supply demand while keeping your inventory as low as possible.

Set Service Levels

Service level, which is measured in percent, defines how available your products are to your customers at any given time.

Our inventory forecasting keeps a relatively lower service level (95%) on items less in demand, which don’t represent the bulk of your sales.

The default settings of 99% and 95% can be changed, but these values are a well-accepted balance between good business sense and satisfied customers.

Automate Replenishment

Effortlessly calculate how much stock needs to be ordered to supply demand

Forecast workflow automation

Create Purchase Orders from forecasts in seconds.

Our inventory forecasting solution automatically creates adjustable purchasing proposals for your review.

When you’re happy, you can generate risk optimized Purchase Orders in Salesorder for each SKU and Supplier in seconds.

Because the inventory forecasting workflow is joined up with Supplier Management you can immediately email and then track these inside your Salesorder system.

Our inventory forecasting includes tools to predict sales resulting from promotion.

Promotion Analysis

The analysis is intended for short promotions (up to 60 days), and it is ideal for one- or two-week promotions, and is performed in three steps.

Estimate what would have been sold in a given period in the past without any promotions.

Forecast product quantities that will be sold in the promotion with the given parameters, i.e. length of the promotion, discount, leaflets, secondary placement, gifts, etc.

Split the forecast quantity of product sold into individual days, based on a typical promotion of the given type.

Promotion forecast calculation

Our Promotion forecast calculation takes into consideration four factors: Pre-promotion effect: the decrease in Sales due to customer anticipation. Promotion effect: the promotion quantities Post-promotion effect: sales decrease due to market saturation after the promotion over an arbitrary or defined period. Cannibalization: decrease in sales due to this promotion.

Forecast extraordinary sales

How to create a Sales Forecast for a Promotion

FAQ

How long before I see the benefits of inventory forecasting?

Inventory management and sales forecasting are complicated disciplines which need high performance computer power to improve over time. Still, it always comes down to making smart decisions in the ordering process.

Clever orders keep your inventory small, your goods available, your customers satisfied, and your bank accounts full. So although creating order lists is an easy process, the implications of these decisions are game changers that can make your business much more successful.

By following our recommendations you will quickly see that we usually recommend ordering less items than you normally would. So from day one you should see a cash saving effect from our service.

When you continue to use our software over time and on a daily basis, you’ll start to benefit from other long term effects of our inventory forecasting. Your stock will reduce in size. You will see that even with a much smaller inventory you are still able to satisfy demand and reduce the amount of stock outs at the same time.

Customers who use our system find that everything we say about our forecasting accuracy is true. And there’s one other critical aspect yet to be mentioned: The more you trust our recommendations, the more you save time in order management. And time, as all wholeslaers know, is the one thing that there is never enough of.

Inventory forecasting versus Sales Forecasting?

Sales forecasting and inventory forecasting are closely related, with one exception. You generally want your sales forecast to go up and your inventory forecast to go down. The best case scenario would be for both to occur simultaneously.

Most entrepreneurs assume that the more you sell, the more inventory you’ll need. At Salesorder.com, we know otherwise. It’s estimated that fifty percent of your inventory is obsolete and you don’t need to stockpile so much inventory to meet demand. That’s why we’re here, to help you reduce inventory, while you keep your service level (or availability of goods for sale) as high as possible.

We want to show you how your inventory will drop, if you use our forecasting algorithms. To make our master forecasting graph more visual, we’ve added a red curve. This little addition shows you how your inventory levels will change over time.

This information is handy in many ways. It’s especially important to keep this in mind when planning your cash flow or renting a new warehouse. Using our inventory forecasting, a typical customer can increase warehouse space availability without compromising on growth.